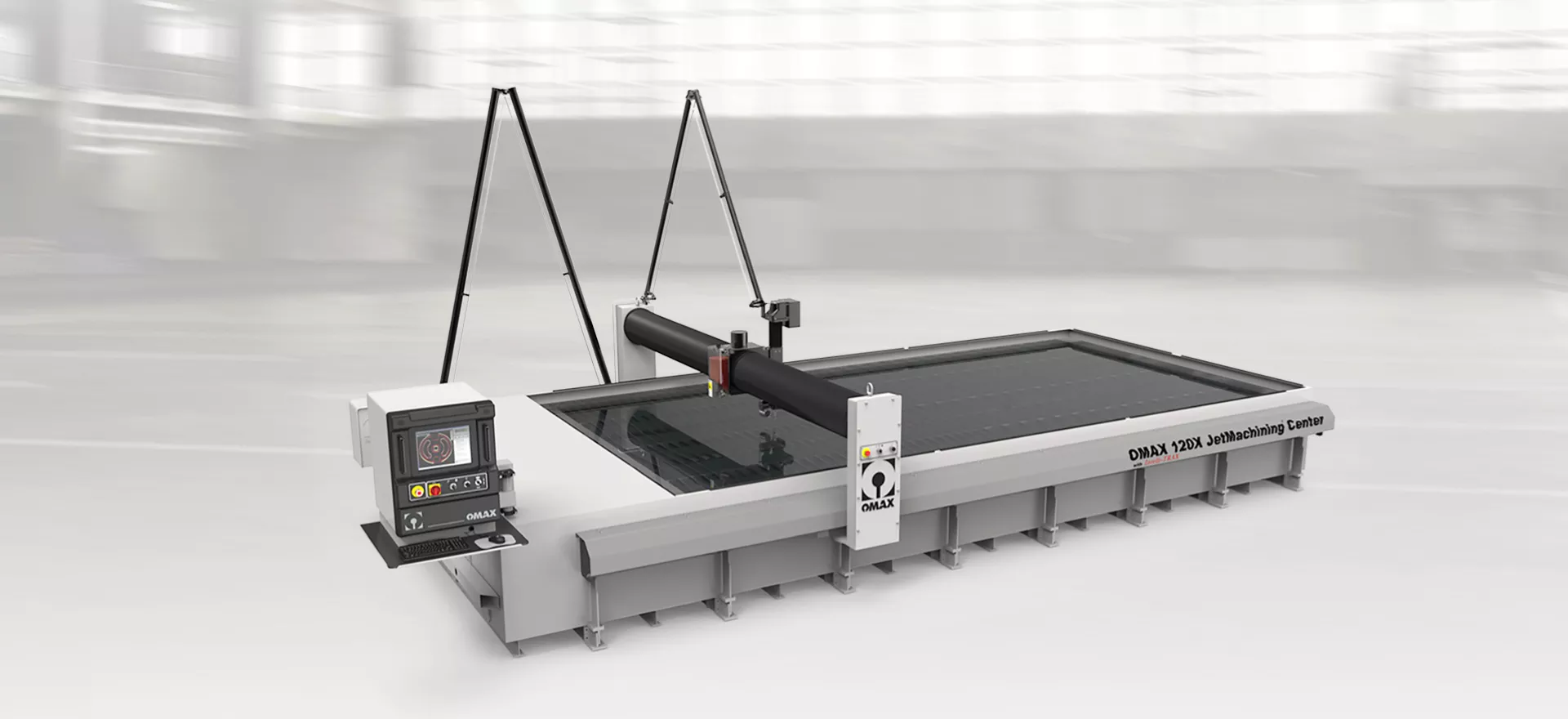

The OMAX 120X is ideal for multiple-part projects or large-scale part production.

- Available in a range of lengths from 33' 3" to 51' 6" feet (10.13 m to 15.70 m)

- ±0.001" (±0.025 mm) linear position accuracy

Expand all

- Backed by our exclusive IntelliMAX Premium Software

- Advanced high-precision IntelliTRAX linear drive technology designed exclusively for the abrasive waterjet environment

- Standard programmable Motorized Z-Axis with a precision OMAX MAXJET 5i Nozzle boosts productivity and process efficiency

- Standard Rapid Water Level Control for cleaner, safer, and quieter submerged cutting completes most work below 80 dBA

- Standard 600 lb Bulk Abrasive Delivery System transports garnet from the assembly's large hopper into the Zero Downtime Hopper located on the Z-Axis

- Standard scissor-style hard plumbing

- Designed and manufactured at the OMAX factory in Kent, Washington, USA

- Does not create heat-affected zones or mechanical stresses

- Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics

- No tool changes & minimal fixturing dramatically reduce setup

DIMENSIONS & SPECS

| 120X-S | 120X | 120X-1 | 120X-2 | 120X-3 | |

| Footprint (with pump) | 26' 7" x 19' 5" (8.10 m x 5.92 m) | 33' 3" x 19' 5" (10.13 m x 5.92 m) | 37' 2" x 22' 5" (11.33 m x 6.83 m) | 44' 1" x 22' 5" (13.44 m x 6.83 m) | 51' 6" x 22' 5" (15.70 m x 6.83 m) |

| Height (with scissor plumbing) | 14' (4.27 m) | 14' (4.27 m) | 14' (4.27 m) | 14' (4.27 m) | 14' (4.27 m) |

| Operating Weight | 58,961 lbs (26,744 kg) | 71,679 lbs (55,997 kg) | 88,937 lbs (44,096 kg) | 106,195 lbs (48,169 kg) | 123,453 lbs (55,997 kg) |

| Weight (tank empty) | 22,000 lbs (9,979 kg) | 22,000 lbs (9,979 kg) | 26,000 lbs (11,793 kg) | 30,000 lbs (13,608 kg) | 34,000 lbs (15,422 kg) |

| X-Y Cutting Travel* | 13' 4" x 10' (4.06 m x 3.04 m) | 20' x 10' (6.09 m x 3.04 m) | 26' 8" x 10' (8.12 m x 3.04 m) | 33' 4" x 10' (10.16 m x 3.04 m) | 40' x 10' (12.19 m x 3.04 m) |

| Z-Axis Travel (with Motorized Z Axis)* | 8" (203 mm) | 8" (203 mm) | 8" (203 mm) | 8" (203 mm) | 8" (203 mm) |

| Table Size | 14' 11" x 11' 5" (4.55 m x 3.48 m) | 21' x 11'5" (6.40 m x 3.48 m) | 28' 3" x 11' 5" (6.40 m x 3.48 m) | 34' 11" x 11' 5" (10.64 m x 3.48 m) | 41' x 11' 5" (12.50 m x 3.48 m) |

| Material Supports Slats | 4" x 1/8" Galvanized Steel |

|---|---|

| Maximum Supported Material Load | 400 lbs/sq ft (1,950 kg/sq meter) |

| Electrical Requirements | 3-Phase, 380-480 VAC ±10%, 50-60 Hz |

| Noise Level | Below 80 dBA at one meter for submerged cutting |

| Speed | 350 in/min (8,890 mm/min) |

| Linear Positional Accuracy* | ±0.001" (±0.025 mm) |

| Repeatability* | ±0.001" (±0.025 mm) |

| Ballbar Circularity* | ±0.005" (±0.127 mm) |

* Accessories may reduce travel. Accuracy specifications are at 72° F (22° C) .

PUMP INFO

Maximized uptime with 1,000 hours between maintenance cycles

Increased production by delivering 30% more cutting power

Variable Frequency Drive reduces startup power consumption and maximizes operating flexibility

| EnduroMAX 100 HP | EnduroMAX 50 HP | EnduroMAX 30 HP | DynaMAX 575P | |

|---|---|---|---|---|

| Motor Power | 100 HP (75 kW) | 50 HP (37kW) | 30 HP (22 kW) | 75 HP (56 kW) |

| MAX Jet Power | 85 HP (63 kW) | 42.5 HP (31.5 kW) | 25.5 HP (18.7 kW) | 51.6 HP (37.9 kW) |

| Output Pressure | 60,000 psi | 60,000 psi | 60,000 psi | 60,000 psi |

| Orifice & Flow Rate ** | 0.022" / 2.25 gpm (0.56 mm / 8.52 lpm) | 0.016" / 1.20 gpm (0.41 mm / 4.54 lpm) | 0.012" / 0.67 gpm (0.30 mm / 2.54 lpm) | 0.017" / 1.5 gpm (0.43 mm / 5.68 lpm) |

| Footprint LxWxH | 44" x 62" x 44" (1,118 mm x 1,575 mm x 1,118 mm) | 66" x 36" x 38.5" (1,676mm x 914mm x 978mm) | 66" x 36" x 38.5" (1,676mm x 914mm x 978mm) | 40" x 79" x 59" (1016 mm x 1996 mm x 1509 mm) |