Educational Institutions

ProtoMAX waterjet helps heroes build better spaces for Philadelphia

Tiny WPA took inspiration from President Franklin D. Roosevelt’s Works Progress Administration (WPA), the depression era workforce development program. It became an official nonprofit by 2014 and continues to build strong relationships with other organizations in Philadelphia. Read

Bendigo Tech School’s Multi-Tasking Abrasive Waterjet

Bendigo Tech School, in Central Victoria, Australia, is a centre of deep learning for secondary students that uses cutting-edge technology, discovery, and innovation to solve real-world problems. Hosted by La Trobe University Bendigo, the tech school provides advanced STEAM (Science, Technology, Engineering, Arts, and Mathematics) programming to prepare young people for the future of work. Read

Missouri S&T: Applying Design Solutions for Today

Due to the ongoing pandemic, manufacturers, fabricators and schools are focused on leveraging their equipment to find creative solutions. With the advancement in machine tool usability, functionality, and versatility, many fabrication spaces are better equipped than ever for both rapid prototyping and high production manufacturing. Because of this, students and staff at Missouri S&T were able to use their MAXIEM 1515 to make a big impact. Read

Fort Lewis College uses waterjet in unusual ways

The 1515 cut the grinding stone, the center piece of the gristmill. “In Nepal, villagers will continue to provide the mill with grinding stones for use with the improved mill frame,” said May. “To simulate this condition, it was necessary for us to fabricate our own grinding stones for laboratory testing. In lieu of using a hammer and chisel, we elected to cut the cylindrical stones plate from granite slabs using the waterjet. Based on measurements made by our NGO partner of the stones in Chyamtang, we cut a series of three identical stones, each with a center shaft hole and tee slot.” Read

High School Robotics meets GlobalMAX

In 2018, Terrell purchased their GlobalMAX 1530 as a way to expand their material cutting capabilities while introducing their students to advanced machining technology. Terrell’s three shops already housed a CNC mill, CNC lathes, full-spectrum lasers, a CNC router, a Kuka Robots, and an array of different 3D printers. “We knew that we had a bottleneck within our production with our router so we went after a solution that would prove to be the key to our problem,” explained Edwards. “We choose OMAX because they are conspiring for the young engineers.” Read

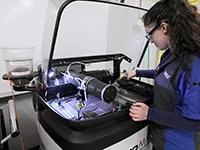

ProtoMAX at PCSC

A video re-visit of our friends at Pierce County Skill Center. Learn how Briston Trapp and his students use ProtoMAX to explore aerospace manufacturing. Read

ProtoMAX Inspires Tomorrow’s Aerospace Fabricators

The Pierce County Skill Center (PCSC) in Puyallup, Washington has installed a ProtoMAX into their Aerospace Manufacturing and Fabrication program to facilitate accurate material cutting while showcasing design and advanced fabrication techniques. PCSC is a vocational training center teaching high school juniors and seniors during the regular school year and 9th thru 12th grades during a three week introductory summer program in a wide range of hands-on professional experiences. Read

Racing Towards The Future At UCLan With The MAXIEM 1515

Upon gaining a better understanding of what the waterjet can offer they have now added a MAXIEM 1515 to the workshop. Paul Critchley, the Principal Technician of the LIS Workshop Services at UCLan, backs their decision by saying, “we came to better realize the merits of a waterjet such as ease of use and flexibility in terms of the huge variety of materials and thicknesses it can cope with.” Read

Autodesk Pier 9: Waterjet Finds its Groove in Maker Culture

One might describe software developer Autodesk’s Workshop at Pier 9 as a traditional communal workspace. But in reality, it is a highly advanced maker space where artists, engineers, designers, architects and others network and share resources and knowledge that blur the lines between art and manufacturing. It is here that an OMAX® 60120 JetMachining® Center helps foster innovative designs and transform how things are made. Read

Talented Local Students Collaborate With OMAX Corporation

The students approached OMAX with their design files to cut aluminum framework, brackets, and wheel holders on a MAXIEM™ JetCutting Center. They produced a lightweight truss out of hollow 4 inch wide tube with 1/8th inch thick interior walls. To ensure clean cuts, they inserted steel into the aluminum tube as sacrificial material. The hands-on experience motivated the students to think about other materials that can be cut on waterjet technology for future projects. Read