Media Center

MEDIA CENTER

Tips and Tricks

Five Reasons Why Waterjet Is Strengthening Defense Manufacturing

Waterjet technology delivers precision, adaptability, and safety—making it essential for modern defense manufacturing. Read

Why 2025 Is a Strategic Year to Buy Waterjet or Plasma Table

2025 offers manufacturers a prime opportunity to invest in waterjet or plasma cutting tables at reduced net cost—thanks to new tax advantages under the One Big Beautiful Bill Act (OBBBA) Read

Four Reasons To Always Use OMAX Genuine Parts

We’ve all done it: snapped up a generic, aftermarket replacement part or consumable in the quest to save a few dollars. But while the desire to cut costs is understandable, how much are we giving up in return for those short-term savings, and is it really worth it in the long run? Read

Press Releases

Hypertherm Associates adds Arabic to OMAX and Hypertherm websites

Hypertherm Associates, a U.S. based manufacturer of industrial cutting systems and software, today announced the addition of the Arabic language to its OMAX® waterjet website. The Hypertherm® plasma website will follow by the end of Q1 2026. This enhancement expands access for customers across the Middle East, North Africa, and Arabic-speaking markets worldwide. Read

Shipbuilders Explore Innovative Cutting Methods at Technical Symposium

Symposium attendees received an in-depth look into Hypertherm plasma cutting technologies, as well as information on OMAX® abrasive waterjet systems, and BLM Group laser machines. Read

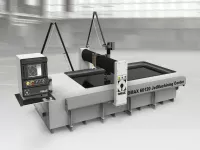

Hypertherm Associates Debuts the New MAXIEM X JetMachining Centers

Now with enhanced features, the MAXIEM brings superior performance, versatility and productivity at an affordable price. It is engineered for shops that require intelligent performance. Every detail has been reimagined to deliver a cutting experience that’s smarter, and more intuitive. Read

News Articles

Jetting to success

A New York-based shop implements waterjet technology and gains value Read

Digging deep

Fabricating projects in the engineering program’s shop helps prepare students for not only continuing their education after high school and, more importantly, for life. Kamal notes that students who are accepted into his program spend more than 1,000 hours studying engineering, including a lot of fabrication in class and as part of the after-school robotics club. Read

Waterjet Case Study: The complete package

Montreal packaging solutions manufacturer continuously invests in automation to keep pace with growth and keep its R&D on point Read

Videos

Using OMAX precision to build OMAX power

At OMAX, we don’t just manufacture world-class waterjet cutting systems—we rely on them every day to build the very machines our customers trust. From precision-cut brackets to custom enclosures and intricate internal components, our own waterjets are integral to our production process. Why? Because we believe in the power of our technology. Read

The OMAX IntelliMAX Saw Function can save you time and inventory space

The OMAX IntelliMAX Saw Function lets you easily program a straight line cut to quickly trim material to shape or remove scrap skeletons. Read

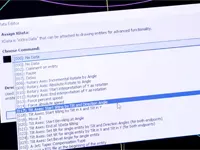

How easy is IntelliMAX XData

The OMAX IntelliMAX software has a powerful tool in its XData commands. Using XData is surprisingly easy to use, too, with only a few clicks needed to change settings on cutting paths. Read