LEARN ABOUT WATERJETS

LEARN ABOUT WATERJETS

WHAT IS A WATERJET?

A waterjet utilizes a high pressure stream of water to erode a narrow line in the stock material. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting. This flexibility greatly enhances the versatility of a waterjet machine, as it can easily switch from cutting ½" (1.27cm) foam gaskets to 4" (10.16cm) titanium brackets.

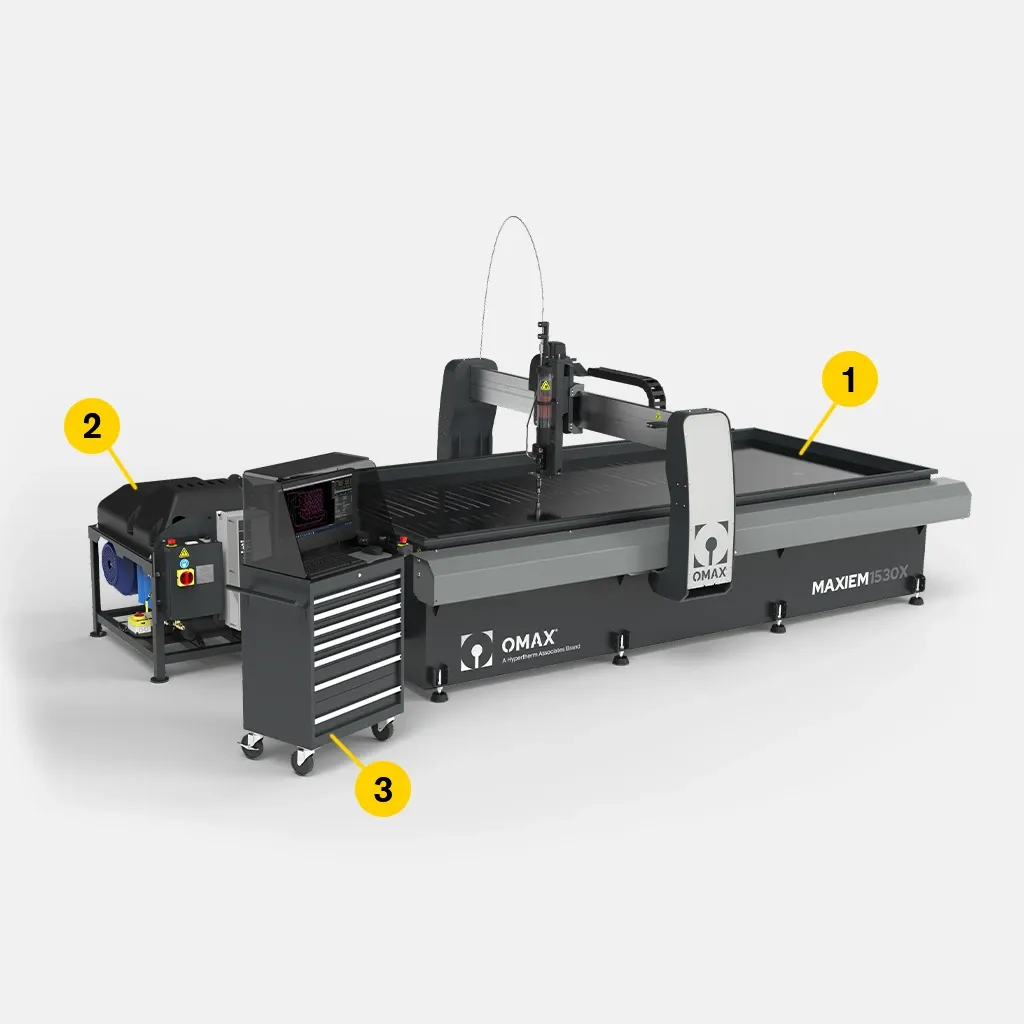

The waterjet cutting machine system consists of three basic components:

The Table

The table is an X-Y nozzle mechanism with garnet hopper attached and catcher tank below.

The Pump

The high pressure pump provides pressurized water for the cutting process.

The Controller

The controller uses software for system operation, motion control, and nozzle positioning.

HISTORY OF WATERJETS

The Beginning

Using water as a cutting method for soft materials has been around for decades. Early forms such as the paper metering system by the Paper Patents Company in the 1930s used relatively low-pressure water. While early waterjets could easily cut soft materials, they were not effective in cutting harder materials. The ability to cut harder materials, such as metals, was achieved by adding an abrasive to the waterjet in the cutting nozzle after the jet stream was formed. But simply inducing garnet was not a viable solution without further advancements. Cutting harder material would take two innovations: ultra-high pressure pumps and advanced waterjet nozzles.

Technological Advances

High pressure waterjet technology took form in the post-World-War-II-era, resulting in faster cutting and greater precision. Reliability remained a challenge until the early 1970s when Dr. John Olsen, VP of Operations at OMAX Corporation, developed the first reliable ultra-high pressure pump.

Commercial Success

Early abrasive waterjet nozzle life was too short to be commercially viable, but material innovations in mixing tubes by Boride Corporation eventually resulted in a commercially acceptable nozzle. With the combination of a durable abrasive waterjet nozzle and a reliable high pressure pump, an abrasive waterjet machine could now cut a wide range of materials, including hardened tool steel, titanium, stone and glass.

Timeline

-

1930s

Low-pressure waterjet system used to cut paper. Abrasive waterjet nozzle concept patented.

-

1940s

High pressure seals developed for aviation & automotive hydraulics

-

1950s

Ultra-high pressure (100,000 psi, 6,900 bar) liquid jet used to cut aerospace metals

Numerical Control (NC) system developed by John Parsons

High pressure waterjet developed to cut plastic shapes

-

1960s

Up to 50,000 psi (3,450 bar) pulsing waterjet created at Union Carbide and cut metal and stone

High Pressure pumps manufactured for polyethylene industry

-

1970s

Bendix Corporation develops concept of using corundum crystal for waterjet orifice

Dr. John Olsen develops and patents the high pressure fluid intensifier

First mainstream commercial waterjet cutting system introduced

-

1980s

Boride Corp. develops ROCTEC ceramic tungsten carbide composite mixing tubes

Evolution of 1930s abrasives nozzle design brings abrasive jet machining to reality

-

1990s

OMAX Corporation established

Dr. John Olsen develops and patents (5,508,596 & 5,892,345) motion control systems to precisely locate the waterjet stream

-

2000s

Cutting model improvements significantly increase cutting speeds in OMAX machines

High precision zero taper waterjet cutting introduced with the Tilt-A-Jet

Affordable and versatile MAXIEM Waterjet line introduced

-

2010s

OMAX Rotary Axis and A-Jet brings 6-Axis machining to OMAX Machines

EnduroMAX Pump Technology significantly increases reliability

IntelliMAX Software Suite adds innovative system monitoring and advanced 3D tools

-

2020s

IntelliMAX upgraded for inter-connectivity, scripting, and advanced monitoring

OptiMAX Waterjet debuts introducing industry 4.0 software and technology to abrasive waterjet

RELATED QUESTIONS

Quite simply, erosion.

A waterjet cutter uses a fine steam jet of water at high velocity and pressure, or a mixture of water and an abrasive garnet particle, into and subsequently through the material you are trying to cut.

Waterjet systems can vary, but most are made up of a high-pressure pump, a cutting table that holds the work material, a nozzle that emits the jet stream, an X-Y motion system to move the nozzle and a PC-based controller. OMAX tables are water-filled tanks with slats that hold the material. The material can be submerged under the water, making the cutting quiet and clean. OMAX waterjets have hoppers that hold and dispense abrasive during the cutting process.

It's easier to answer what materials can't be cut with a waterjet. An abrasive waterjet can cut virtually anything, but we don't recommend cutting tempered. Waterjet can cut aluminum, brass, bronze, carbon fiber composite, ceramic, copper, fiberglass, glass, granite, Kevlar, marble, stainless steel, titanium, tungsten and a lot more. Many food processing companies do use pure waterjet machines (rather than abrasive waterjets) to cut food.

- Abrasive waterjets can cut virtually any material, including glass and reflective materials, and a wide range of material thicknesses. Some OMAX customers report cutting material up to 18 inches thick.

- Abrasive waterjet machining is a cold cutting process and creates no heat-affected zones (HAZ), therefore it doesn't change the material properties or leave heat-hardened edges.

- Set-up for cutting jobs on abrasive waterjets is quick and easy.

- Multiples of the same part can be cut at one time from different types of material simply by stacking the various sheets of material on the waterjet.

- No harmful vapors are emitted with abrasive waterjet cutting.

- A waterjet's cutting tool never gets dull.