OMAX NEWS ARTICLES

Jetting to success

A New York-based shop implements waterjet technology and gains value Read

Digging deep

Fabricating projects in the engineering program’s shop helps prepare students for not only continuing their education after high school and, more importantly, for life. Kamal notes that students who are accepted into his program spend more than 1,000 hours studying engineering, including a lot of fabrication in class and as part of the after-school robotics club. Read

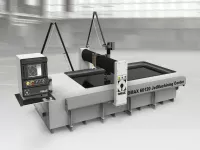

Waterjet Case Study: The complete package

Montreal packaging solutions manufacturer continuously invests in automation to keep pace with growth and keep its R&D on point Read

Brains + beauty

“Based on my experience constructing robots, and my background developing software for the web, I decided to build a website and business that made it easier for people to order custom, high-quality parts online,” explains Arthur. Read

How a waterjet helps to bring characters to life for Nashville designe

Animax Designs from Nashville, TN, uses a MAXIEM 1530 abrasive waterjet water jet cutter in this 2021 article from the Fabricator magazine. James Hudak has called the waterjet a “game-changer” in being able to meet the requests of customers, both internally and externally. Read

Tips to Increase Abrasive Waterjet Efficiency

Savvy fabricators with a handful of shortcuts and hacks are able to enhance their productivity while using the same technology that everyone else is using. Here are some tips to increase your design, programming and control know how for more effective use of your abrasive waterjet. Read

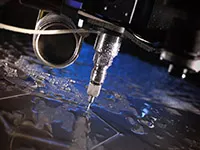

Let Abrasive Waterjet Cutting Fill the Gaps in Your Contract Metal Fab

Waterjet cutting compares favorably with other methods used to cut metal-alloy sheet and plate, offering reliable accuracy, quick setup time and fast cutting of a wide range of materials, without creating a heat-affected zone (HAZ) or altering material properties. Read

Predict & Prevent

Mike Robinson, customer service supervisor at OMAX Corp., says that “every one” of the Kent, Washington-based waterjet manufacturer’s customers who have instituted a PM program for their equipment “has found some measure of good results.” Read

Up and running

Steve Ulmer, vice president of sales at Omax Corp., fully understands the pain points associated with breakdowns, and notes the company has made customer service and tech support part of the foundation of the organization. “Any machine you buy can be the best piece of equipment or machinery you’ve ever bought,” he says, “but without good technical support, without good training and customer service, that machine can be rendered useless.” Read

Optimizing your waterjet production

The best abrasive waterjet machines on the market are designed for rigorous machining. A combination of meticulous mechanics, rigid construction, and velocity control from the software ensures the highest degree of repeatable precision in the machined parts. However, even with all that built in, you can hone the machining process further by using your waterjet to the best of its abilities. Read