Manufacturing

Revolutionizing the Bit and Spur Business with the ProtoMax

When it comes to the art and craft of making bits, spurs, and custom silver pieces, the challenges are as intricate as the designs themselves. For a bit and spur maker like Rod Teuscher, efficiency, precision, and creativity are essential to thriving in an industry where custom designs set artisans apart. Rod’s journey with the ProtoMax waterjet is a testament to how innovation can transform a business. Read

Norsk Titanium Improves Its Manufacturing Process with OMAX Waterjet

Norsk Titanium produces near net shape forging replacement parts for aerospace, defense, and industrial applications using a wire additive process called Rapid Plasma Deposition (RPD®). The company has a facility in Plattsburgh, NY, where it operates its RPD® machines and delivers its parts to customers worldwide. Read

Pardieck Adds Precision Mitering with Waterjet

Pardieck Stone & Tile gained a large advantage in high-end architectural stone construction by adding a MAXIEM abrasive waterjet system equipped with the 5-axis A-Jet cutting head. With the precision of the OMAX IntelliMAX software coupled with the angle cutting capabilities of the A-Jet, Pardieck is able to consistently and cleanly miter sintered stone panels for an impressive finished look that their customers appreciate. Read

Rubikon Text Ltd. Achieves Taper-Free Machining on an OMAX

Rubikon is a small family business that specializes in sewing machine manufacturing as well as fabricating parts for the packaging industry. In 2017, Rubikon brought in an OMAX 60120 with a Tilt-A-Jet to boost turnaround time and an increase in material versatility. Read

Stratford Gates Finds New Opportunities with an OMAX Waterjet

Stratford Gates has long produced some award-winning custom gates for properties of all sizes. See what they discovered when they added an OMAX 60120 JetMachining Center to their existing equipment. Read

OMAX Helps Fabricator Rein in Costs and Expand into New Markets

Impressed with what they had learned about waterjet technology so far and wanting to learn more, Lorena and Randy decided to visit the OMAX manufacturing plant in Kent, Washington that same week. "We toured the OMAX facility and had a really good experience, the hospitality was excellent," describes Randy. Read

Waterjet Expands Possibilities at Valve and Pipe Manufacturer

With the abrasive waterjet process selected, CEAP then turned to finding the right machine for their production. The answer was the DualBridge OMAX 120X JetMachining Center equipped with an A-Jet and a Tilt-A-Jet cutting heads, a Rotary Axis, and a 50 HP EnduroMAX pump. With the DualBridge, CEAP could cut two independent projects simultaneously on one machine, significantly improving productivity. Read

Food-Tech 2002's MAXIEM Enables Speed & Versatility

Food-Tech 2002 in Hungary uses their MAXIEM 1530 to cut stainless steel for canning & refrigeration equipment production. Citing economic and uptime advantages, Food-Tech 2002 has utilized waterjet as a central element in their shop. The versatility of the waterjet allows the company to cut plastic, aluminum and others of multiple sizes. Read

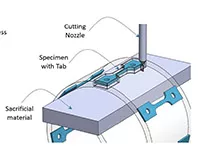

Element Materials Relies on MAXIEM Waterjet for Perfect Sampling

When it became cost prohibitive to continue to outsource forging cut ups, Element brought waterjet cutting in house at its location in Fairfield, Ohio, in the form of a MAXIEM 1515 abrasive waterjet that delivers high performance in a compact package. Read

Contemporary Jewelry by way of ProtoMAX

"The biggest benefit [of the ProtoMAX] has been the addition it brings to the creative process. By removing long waits for cut parts, we are able to bring products to market much more quickly. We can design and cut something in a fraction of the time we used to, allowing us to keep focused on the design we are trying to make,” said Chris Ploof owner of Chris Ploof Designs. Read