OMAX NEWS ARTICLES

Compact Waterjets: The Perfect Teaching Tool

Full-size industrial abrasive waterjets cost less than conventional chipmaking machines. Their drawback is their large size; many schools struggle to make room for waterjets. Now, compact machines offer their full-size counterpart’s benefits to teachers in a fully enclosed, cost-effective platform. Read

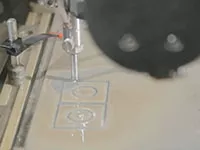

Compact Cutting

The OMAX Corporation’s GlobalMAX 1508 JetMachining Center cutter can offer a happy alternative to traditional large bulky waterjets. The GlobalMAX provides precision abrasive waterjet technology at a price point that won’t break the bank and in a footprint that won't take over too much of a shop's floor space. Read

Bringing real-world metal fabricating to college

Then he came across the ProtoMAX waterjet cutting machine from OMAX. The unit, which has a footprint of 41.5 by 39.5 in., a height of 56.5 in., and sits on four casters, was perfect for the lab. "I saw that little guy and knew we could wheel it right into the lab. It has a cover. It runs like a waterjet. So I called up OMAX right away," he said. Read

Cutting versatility a must at custom boat shop

“Not only did we see the immediate positive impact insourcing had on cost, we also gained speed in the fabrication of our vessels by being able to cut parts whenever needed on-site,” Michell said. “A vessel build takes the better part of two to three months. If we had to outsource our cutting, that could add an additional four to six weeks.” Read

Abrasive Cuts

“Titanium is notorious for wearing out “hard” tools,” Said Vlad Bucur, Applications Lab Supervisor for OMAX Corporation. “Waterjet erodes the material and there is no tool wear in the classic sense. Only the wear on your mixing tube, which remains constant due to the constant abrasive usage. Read

Waterjetting: Get on script

Omax Scripting is a complete but basic programming environment, compiler and execution system built right into Omax’s IntelliMAX Layout and IntelliMAX Make waterjet software. Read

Fundamentals of Waterjet Cutting: Optimum Efficiency

While most users of abrasive waterjet water jet cutting profess its ease of use, anyone that owns a waterjet will admit that while cutting a one-off part might be easy, producing thousands of the same part, with 0.05-in. tolerance, requires knowledge and skill. The difference comes down to understanding process fundamentals and how they work together. Read

Meeting Standards

Abrasive waterjets can work as a valued solution for all types of metallurgy testing. By cutting testing coupons on a waterjet, some manufactures are seeing up to nine times faster preparation speed. Read

Right On Track

It’s almost certain that everyone has seen or stood on Mondo rubber flooring, whether they know it or not. It’s used for track and field surfaces in the Olympic games, and it’s installed in professional sports venues, academic athletic facilities, gyms and even hospitals around the world. Read

The pressure behind abrasive waterjet cutting

Since the inception of waterjet technology nearly 50 years ago, there has been an ongoing argument concerning what combination of pressure and power results in optimal cutting performance. Do bigger numbers translate into better or faster cutting? What combination of pressure, horsepower, and nozzle assembly is best for a given application? What does all this really mean? Read