Tips & Tricks

The Smart Choice: Buying American-Made Machine Tools

Choosing the right manufacturer is critical for ensuring high performance, durability, and long-term value when purchasing machine tools. In an increasingly globalized economy, many companies are tempted to outsource production to cut costs. That may not be the right option. Read

Abrasive Waterjet Machines: The Cutting Edge for Defense Manufacturing

Learn how abrasive waterjet cutting technology from OMAX provides efficient, flexible and profitable part processing for the defense industry. Read

Revolutionize Your Workflow: Add Waterjet Cutting

Enhance your shop’s capabilities with waterjet cutting technology. Discover how abrasive waterjets offer unparalleled versatility, allowing you to cut through diverse materials, reduce outsourcing costs, and minimize waste. Boost your profitability and efficiency by integrating waterjets into your workflow, regardless of your shop size. Explore OMAX's range of waterjet machines and transform your business today. Read

OMAX Order: The One-Stop Shop for Ordering OMAX Parts and Services

OMAX Order is OMAX’s innovative digital solution that puts guaranteed service and support in the palm of your hand with your abrasive waterjet cutting. This mobile app creates convenience, maintains efficiency and provides peace of mind for both your business and everyone on the shop floor. Read

The Significance of Scissor Plumbing in Waterjet Cutting

Scissor plumbing is a flexible and dynamic arrangement of high-pressure lines within a waterjet cutting system. It allows for movement along multiple axes without restricting water flow or abrasive. Read

Waterjet Proves a Perfect Fit for Lean Manufacturing Principles

Discover how waterjet technology aligns seamlessly with Lean Manufacturing principles, enhancing value, workflow efficiency, and the pursuit of perfection in today's manufacturing landscape Read

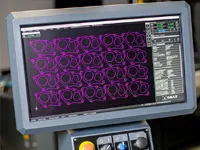

IntelliMAX Software Amplifies Waterjet Efficiency

Enhance the efficiency of waterjet cutting with the IntelliMAX Software Suite, for enhanced versatility, precision, and minimal waste. Discover how its functions optimize tool path, design and material usage for maximum efficiency. Read

IntelliTRAX: The Maintenance-Free Drive System

The IntelliTRAX Maintenance-Free Drive System represents a significant leap forward in waterjet machining. Read

Four Steps to Increasing Efficiency

Efficiency is the ultimate key to any successful operation. Without it, the quality of your waterjet and facility will drastically drop below standard optimization. Read

Made in America: The Story of OMAX Waterjets

One of the critical pillars of OMAX's success lies in its unwavering commitment to vertical integration. By consolidating all manufacturing processes within a single campus, the company ensures seamless coordination between departments, from hardware production to software development to training and support. This holistic approach streamlines operations and results in a superior end product with intuitive design and unparalleled performance. Read