Tips & Tricks

Emergency Prep for your Waterjet

Whether it is hurricane, floods, or whatever else might come your way, OMAX is committed to aiding you get your business back to normal with personnel available both by phone and in-person. Read

Before You Move Your Waterjet...

As your workshop or factory floor evolves, you may find that the original placement of your OMAX abrasive waterjet isn’t quite what works best for your needs. Or… you may be expanding to a larger facility to accommodate more machinery. Whatever the reason, when you start to think of moving your waterjet, there are a few things OMAX customer support would like you to consider. Read

Still in Washington State

In 1993, OMAX Corp. started in Washington State. Twenty-five years later, OMAX is still there. This doesn’t mean the headquarters is located in the Pacific Northwest and the production is spread to whatever country can make the product the cheapest, no. Read

Precision Practices: Tabs and Bridges

Tabs are small pieces of material that hold parts to prevent them from sliding into the tank or being moved by the abrasive jet. They are mostly used with thin materials (because a tab in thick material can be difficult to break). Programming a tab into a tool path allows for several advantages. Read

When it’s Time to Remove Solids

At some point the solids will build up so much that it will affect your waterjet’s efficiency and accuracy. How much cutting you do determines how often you will need to remove solids from your tank. When that time comes, you’ll need to remove those solids to continue your waterjet operations. Read

Precision Practices: Homing

Homing an abrasive waterjet is the process of establishing a location on the machine’s cutting table where the nozzle can be moved in a repeatable way. An absolute home is usually established at the bottom left corner of the machine. This is a fixed point that determines all other points on your cutting table. Read

Preparing for Your Waterjet

If you are waiting for your newly purchased OMAX abrasive waterjet to arrive, or you’re just thinking of adding an OMAX to your shop, you’ll want to make sure your facility is prepared to use your new machine. Below is an overview of general requirements you’ll need to consider before the OMAX installation technician arrives at your location. Read

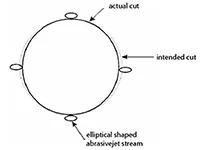

Precision Practices: Kerf and Tool Offset Adjustment

The mixing tube on your OMAX abrasive waterjet is made from ROCTEC composite carbide; however, it will wear with 60,000 psi of abrasive running through it. Below is the image of a mixing tube cross section. This mixing tube had been used for 152 hours. You can see the changing width due to the abrasive wear producing distortion throughout the tube. Read

Precision Practices: Tool Offset

The material and thickness will be determined by what you are cutting. Tool offset is the distance that the tool has shifted away from the cut path to compensate for the diameter of the jetstream (kerf). Note that the offset itself is usually half the width of the kerf. Read

Creating a Technical Support Report

Often when you experience an issue that may need customer support, support may ask you to run and submit an OMAX Technical Support Report. This report includes most of the information the technical support staff will require to understand your problem. In addition, the Technical Support Report allows OMAX to reproduce your problem at OMAX (the report includes your settings files, which can be loaded into MAKE to exactly reproduce your settings). In other words, you will get a faster and accurate answer if you e-mail the Technical Support Report. Read